Dense Phase Pressure Conveying Systems

Dense Phase Pressure Conveying Systems generally use compressed air to push materials through a conveying line to its destination. To be more specific, this system operates in the following manner:

This type of system generally operates on a batch basis in which the pressure vessel is repeatedly filled with powder, pressurized and emptied. A panel of supplementary air valves and sensors may even be used to control the air pressure in the pipe and the velocity of the material at intervals throughout the system to ensure the smooth conveying of the material. This also allows the flow of the material to be stopped and started again with relative ease.

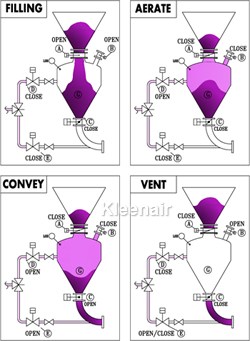

FILL

The Dense Phase Transporter is filled by operating the inlet valve A. The Vent valve B remains open to permit continuous venting. Material dischatge valve C and air admission valves D, E are closed. When set weight of material (sensed by high level switch ) has entered the transporter Fill cycle is completed and valve A closes automatically.

AERATE

Aeration and Pressurization start following completion of a fill cycle. The valves A,C, and B are closed. Air admission valve D opens to start the aeration and pressurization cycle. Air diffuses into the material in the upper chamber G. When the pressure in the transporter increases to the preset pressure thetransporter is ready for Convey cycle

CONVEY

With the completion of pressurization the conveying valve E opens. The discharge valve C is opened and the material is conveyed to the delivery point. The fluidizing air valve D and the discharge valve close as soon as the transporter is empty. The valve E closes after the material in the line is expelled out.

VENT

With the closure of discharge valve C, the vent valve B opens to depressurize the transporter. The transporter is now ready for the next fill cycle.

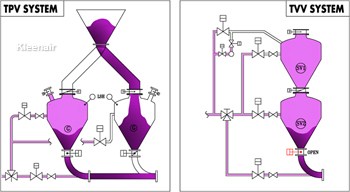

TWIN PARALLEL/TWIN VERTICAL VESSEL SYSTEM

Dense phase conveying using single vessel is always discontinuous batch type conveying. In order to achieve continuity in conveying Kleenair offers Twin Vessel Configuration either in parallel mode or Vertical mode. In order to achieve continuity in conveying Kleenair offers Twin Vessel Configuration either in parallel mode or Vertical mode.

|

|